High speed steel rolls

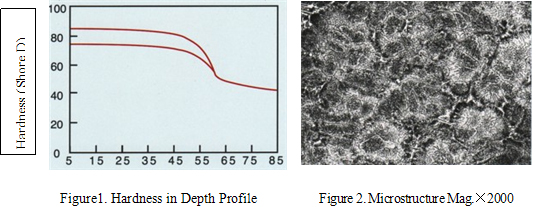

High speed steel centrifugal composition roll is high-carbon alloy steel in which outer layer containers Cr Mo W V Ni and Nb,and the complicated carbide structure are embedded in tempered martensite structures for controlling carbon content and comprehensive heat treatment,optimizing wear resistance and heat fatigue resistance.The surface structure with thin thickness oxide keeps the lower balance stress.

Mechanical properties

Mechanical properties | Data |

HSS rolls surface hardness | HSD70-95 |

HSS rolls neck hardness | HSD35-48 |

Tensile strength of core | ≥450Mpa |

Chemical composition

C | Si | Mn | Cr | Mo | W | V | Nb |

1.4-2.4 | 0.4-0.8 | 0.2-0.8 | 3.0-7.0 | 1.8-7.0 | 1.0-4.0 | 2.0-7.0 | 0.5-5.0 |

Application

High speed steel roll is widely applicable to hot-rolled strip steel working rollF1-F3 mills,pre-finish rolling mill of high speed wire mills and re-bar finish rolling split stand.

High speed steel roll package

By adding elements such as tungsten, molybdenum and vanadium, the hardness can reach 90-95HSD, and the service life is 2-3 times that of traditional Cr5 rollers. It features high hardness, high wear resistance and good thermal stability. High-speed steel contains a large amount of alloying elements such as tungsten, molybdenum, chromium and vanadium, forming complex carbides, which enables it to maintain high hardness and strength at high temperatures and withstand higher rolling speeds and rolling forces.

Scope of application: Mainly used for rolling high-precision and high-performance cold-rolled products (such as high-strength automotive steel), such as ultra-thin strip steel, precision alloy strip steel, etc. It is particularly suitable for high-speed rolling and the rolling of materials that are difficult to deform.